Understanding the Different Types of Industrial Flooring Options

In today’s evolving industrial spaces, flooring plays a significant role, not just in the aesthetic appeal, but in safety, efficiency, and longevity. Industrial environments often demand flooring solutions that can withstand heavy loads, resist chemical spills, and provide safe workspaces for workers. At Extreme IFC, we’ve had decades of hands-on experience as industrial flooring contractors. Let’s explore some of the most popular types of industrial flooring options available today.

Epoxy Flooring

What it is: Epoxy resins are a type of thermosetting polymer, that when mixed with a hardener, chemically react forming a rigid and strong material. The created material offers a variety of different benefits that can be uniquely tailored to suit each individual environment.

Advantages: Epoxy flooring is known for its durability, easy maintenance, longevity, and its variety of decorative aesthetics. It’s also seamless and non-porous, meaning it doesn’t trap dirt or debris and is easy to clean.

Best for: commercial, industrial, and residential areas

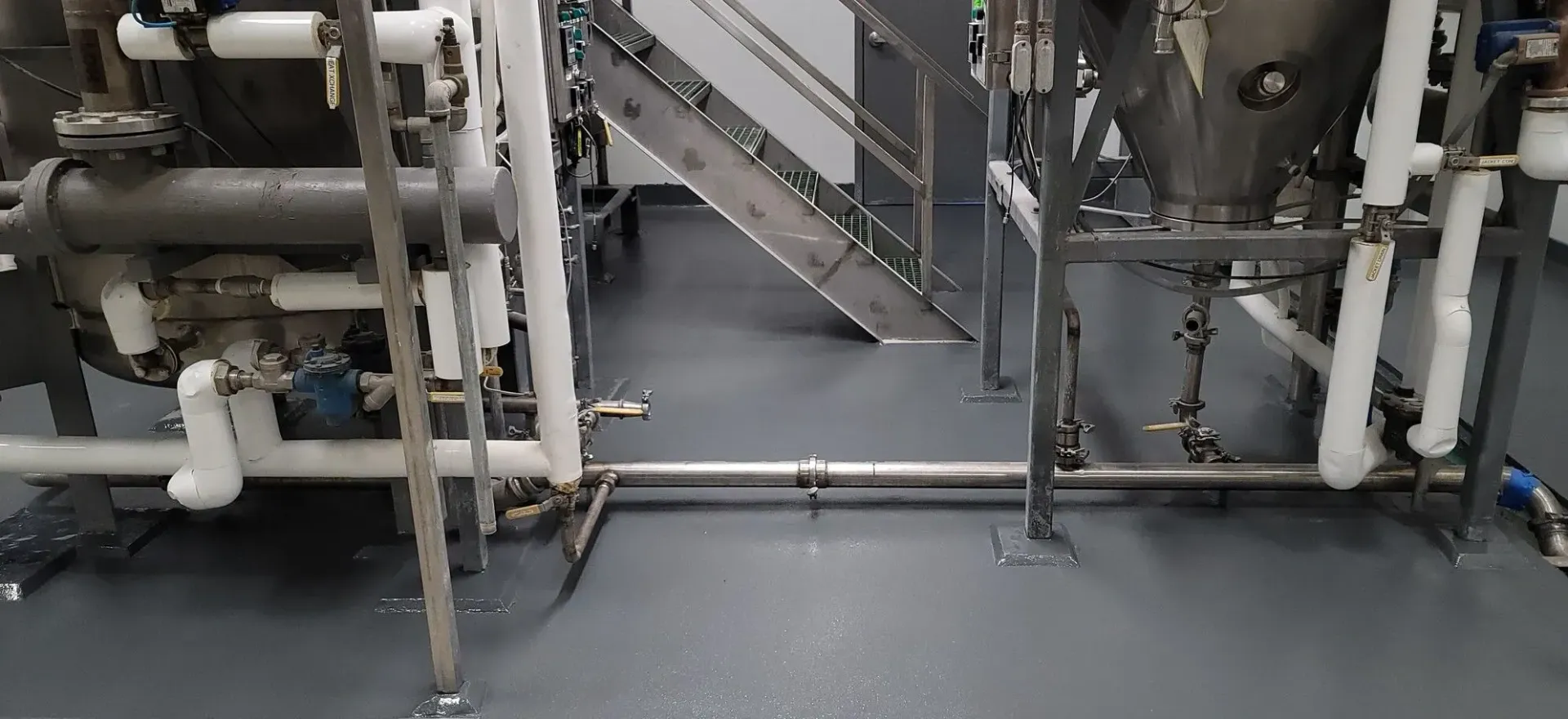

Urethane Cement Flooring

What it is: Urethane cement is a moisture tolerant product that is specifically designed to withstand extreme conditions and provide exceptional resistance to thermal cycling / shock, heavy impacts, chemicals, and abrasion.

Advantages: It’s moisture tolerance, durability, cleanability, chemical resistance, thermal cycling / shock capabilities, slip resistance, and can elevate substrate defects depending on thickness.

Best for: food and beverage, commercial kitchens, pharmaceuticals, manufacturing, high-demand environments

Polished Concrete

What it is: A mechanically ground concrete surface treated with densifiers and polished to various levels of shine.

Advantages: It’s cost-effective, long-lasting, and can resist heavy traffic. Additionally, it’s easy to clean and can be customized for desired sheen levels.

Best for: Retail outlets, warehouses, and showrooms.

Breathable Water Based Flooring

What it is: A type of epoxy coating system that allows moisture vapor to pass through the coating while still providing a protective barrier.

Advantages: moisture tolerant, reduces risk of delamination, eco and budget friendly

Best for: Basements, garages, high humidity environments, restrooms, restaurants, gas stations

Electrostatic Dissipative (ESD) Flooring

What it is: A specialized flooring designed to dissipate any static discharge. ESD flooring controls static by providing a path for the built-up electrical charges to safely ground. This is crucial in environments where even a small static charge can be disastrous.

Advantages: It prevents static build-up, which can be harmful in certain industries. It’s also durable and can resist heavy traffic. Easy cleanability and long

Best for: Electronics manufacturing units, aerospace, server rooms, data centers, labratories, and any industry dealing with chemical and explosive materials.

Choosing the Right Option

The choice of industrial flooring depends on various factors: the nature of the industry, the kind of traffic expected, potential chemical exposures, and, of course, budget considerations. An essential factor to remember is installation. Even the best flooring material can underperform if not installed correctly.

That’s where we, at Extreme IFC, come in. As leading industrial flooring contractors, our team has the expertise to guide you through the multitude of options, ensuring you choose the one that aligns perfectly with your needs and budget. With proper installation, the right industrial flooring can serve you for years, ensuring safety, functionality, and aesthetic appeal.

To explore more about the industries we serve and how we can revolutionize your space, visit our page: Extreme IFC Industries Served.

In conclusion, the right flooring does more than just complete a space. It ensures safety, efficiency, and longevity. As the world continues to evolve, so do our flooring solutions. It’s all about finding the perfect balance between form and function, and at Extreme IFC, we’re here to help you strike that balance.