Cutting Maintenance Costs: Why Polished and Resinous Concrete Outperform Conventional Floors

Facility maintenance isn’t just about keeping things clean—it’s about saving time, reducing labor, and minimizing long-term expenses. When it comes to flooring, the material you choose plays a major role in how much you’ll spend on upkeep over time.

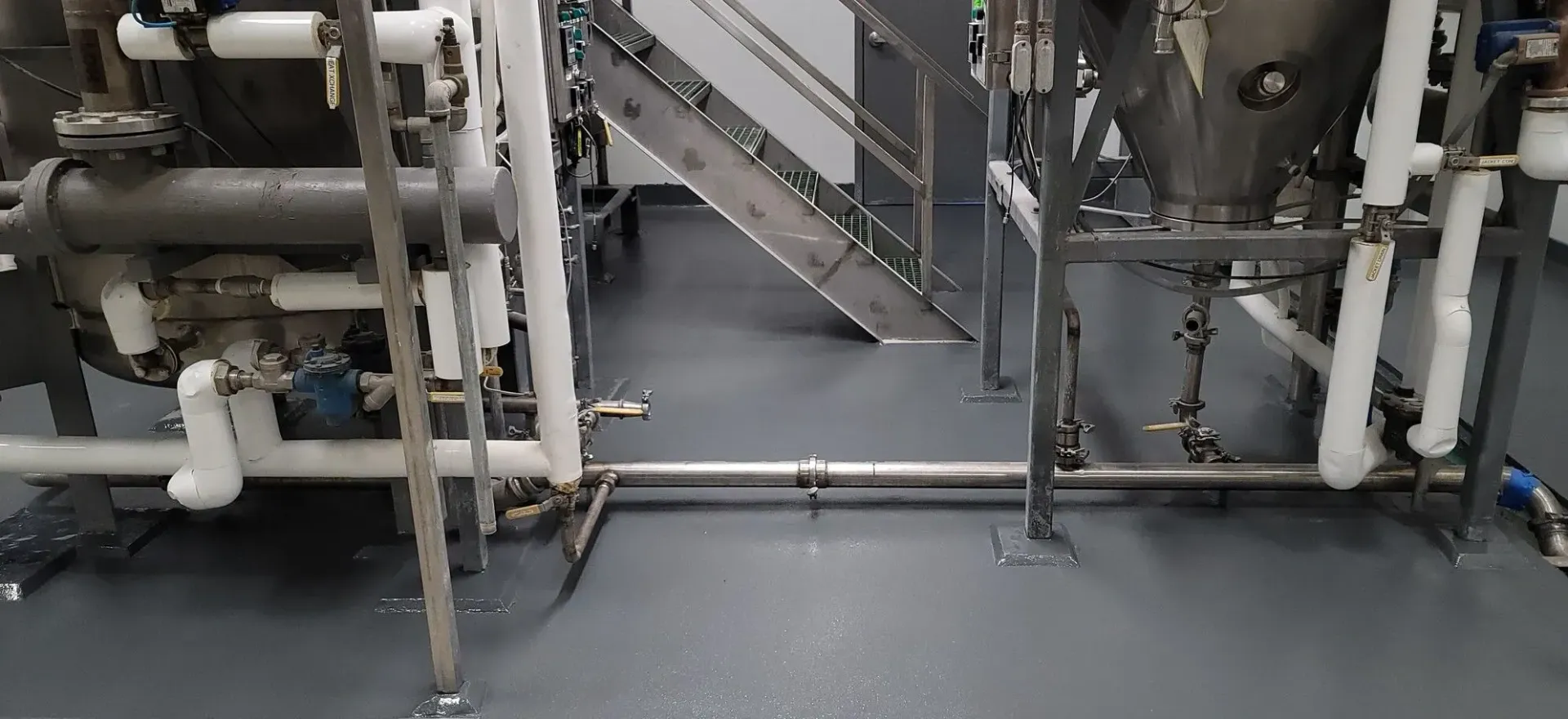

Polished and resinous concrete flooring systems have become the top choice for facilities looking to cut maintenance costs without sacrificing performance or appearance. Whether you're managing a warehouse, a manufacturing plant, or a high-traffic commercial space, upgrading your floors could significantly reduce your ongoing maintenance spend.

Let’s take a closer look at why polished and resinous concrete outperform traditional flooring options like tile, VCT (vinyl composite tile), and bare concrete.

Facility maintenance isn’t just about keeping things clean—it’s about saving time, reducing labor, and minimizing long-term expenses. When it comes to flooring, the material you choose plays a major role in how much you’ll spend on upkeep over time.

Polished and resinous concrete flooring systems have become the top choice for facilities looking to cut maintenance costs without sacrificing performance or appearance. Whether you're managing a warehouse, a manufacturing plant, or a high-traffic commercial space, upgrading your floors could significantly reduce your ongoing maintenance spend.

Let’s take a closer look at why polished and resinous concrete outperform traditional flooring options like tile, VCT (vinyl composite tile), and bare concrete.

Easier and Faster to Clean

Polished and resinous concrete floors are smooth, seamless, and non-porous—making them incredibly easy to clean. Dust, dirt, and spills stay on the surface instead of soaking in, which makes daily maintenance quick and efficient.

Compare that to tile grout lines or unfinished concrete, which tend to collect debris, harbor bacteria, and require more aggressive cleaning efforts.

Pro Tip: With the right maintenance plan, polished or coated concrete floors can be cleaned with basic tools—just auto-scrubbers or mop systems and a pH-neutral cleaner.

Resistant to Stains, Chemicals, and Wear

In demanding environments like industrial facilities or warehouses, spills and chemical exposure are inevitable. Resinous floors (like epoxy and urethane systems) are specifically designed to resist:

- Oils and solvents

- Cleaning agents

- Acids and alkalis

- Moisture and water intrusion

Polished concrete, when sealed properly, also repels most stains and resists surface wear far better than untreated concrete or porous materials.

Did You Know? Resinous floor coatings form a barrier layer that protects the substrate from long-term damage, reducing the need for costly repairs.

Long-Term Durability = Fewer Repairs

Traditional flooring materials like vinyl, tile, and even some laminates are prone to cracking, delaminating, or peeling over time—especially in high-traffic or heavy-load environments.

In contrast, properly installed concrete coatings and polished systems are engineered for longevity. They resist abrasion, impact, and UV degradation, often lasting 10–15+ years with minimal maintenance.

Why it matters:

The longer your floor lasts without needing replacement or patching, the more you save in both materials and downtime.

No Grout Lines or Seams to Maintain

Floors with grout lines (tile, brick pavers) or seams (rolled flooring) require extra attention to prevent cracking, separation, and hygiene concerns.

With polished concrete and resinous coatings, the surface is seamless—meaning no edges, joints, or seams to scrub, seal, or repair. This is especially beneficial in environments where cleanliness and compliance are top priorities.

Facilities that benefit most:

- Food & beverage processing

- Healthcare and labs

- Warehousing and logistics

- Automotive and maintenance bays

Lower Total Cost of Ownership

When you factor in cleaning labor, equipment wear, repair cycles, and product replacement, traditional flooring systems often cost more over time—even if they seem cheaper upfront.

- Concrete-based solutions reduce those costs by:

- Requiring fewer specialized maintenance steps

- Lasting longer without failure

- Withstanding tough conditions year-round

- Reducing downtime and disruption

Did You Know? Polished concrete can reduce annual floor maintenance costs by up to 60% compared to waxed VCT systems.

FAQs: Maintenance Savings with Concrete Floors

Are polished or coated concrete floors slippery?

They can be finished with slip-resistant additives or textures. Many systems meet or exceed OSHA standards for floor safety.

How often do concrete floors need to be recoated or re-polished?

Polished concrete may only need light touch-ups every few years. Resinous coatings typically last 10+ years, depending on the environment.

Will I need to shut down my facility for installation?

Not necessarily. Many modern flooring systems offer fast-cure options, allowing for phased or overnight installations with minimal disruption.

Reduce Costs from the Ground Up

Your floor is one of the hardest-working surfaces in your facility—so it should be built to perform. Upgrading to polished or resinous concrete flooring can drastically cut maintenance costs while improving cleanliness, safety, and durability.

At Extreme IFC, we specialize in installing high-performance industrial flooring systems designed to save you time, money, and hassle. Whether you’re upgrading an outdated floor or starting fresh in a new space, we’ll help you find the solution that fits your operational goals.

Ready to explore cost-effective flooring options? Contact Extreme IFC today for a free consultation.