Flooring Solutions for Manufacturing Plants: Handling Heavy Machinery & Traffic

Manufacturing plants are some of the most demanding environments when it comes to flooring performance. From forklifts and heavy-duty machinery to foot traffic and chemical exposure, floors in these settings need to do more than just stay intact—they must enhance safety, reduce maintenance, and withstand years of wear without breaking down.

If you're managing a manufacturing facility, selecting the right flooring system isn’t just about aesthetics—it’s about function, longevity, and protecting your bottom line. Here’s a look at the top-performing flooring options designed specifically to meet the high-impact needs of manufacturing operations.

Why Flooring Matters in Manufacturing Plants

The flooring in a manufacturing plant has to hold up under significant pressure. Beyond heavy equipment, floors must handle:

- Continuous foot and forklift traffic

- Abrasive debris and dropped tools

- Exposure to oils, chemicals, and solvents

- Thermal fluctuations and moisture

Using the wrong flooring system can lead to cracks, stains, safety hazards, and costly shutdowns for repairs or replacement.

Key Requirements for Manufacturing Facility Flooring

A successful flooring system in manufacturing environments should offer:

- Load-Bearing Strength

Heavy machinery and equipment place immense pressure on flooring. A durable solution prevents structural damage, chipping, or cracking over time. - Impact and Abrasion Resistance

Dropped parts, dragged pallets, and abrasive particles can wear floors down fast. The right flooring solution resists surface damage to maintain performance and safety. - Chemical Resistance

In areas exposed to oils, coolants, and corrosive chemicals, chemical-resistant coatings are essential to prevent staining, breakdown, or hazardous contamination. - Slip Resistance

Moisture, spills, and debris can create slippery surfaces. Slip-resistant additives can be incorporated into coatings to reduce fall risks. - Easy Maintenance

Floors should be easy to clean and maintain to minimize production disruptions and reduce cleaning costs.

Best Flooring Solutions for Manufacturing Plants

Here are the most reliable flooring systems for high-demand industrial settings:

1. Epoxy Flooring Systems

Ideal For: Heavy machinery, forklift traffic, and chemical exposure

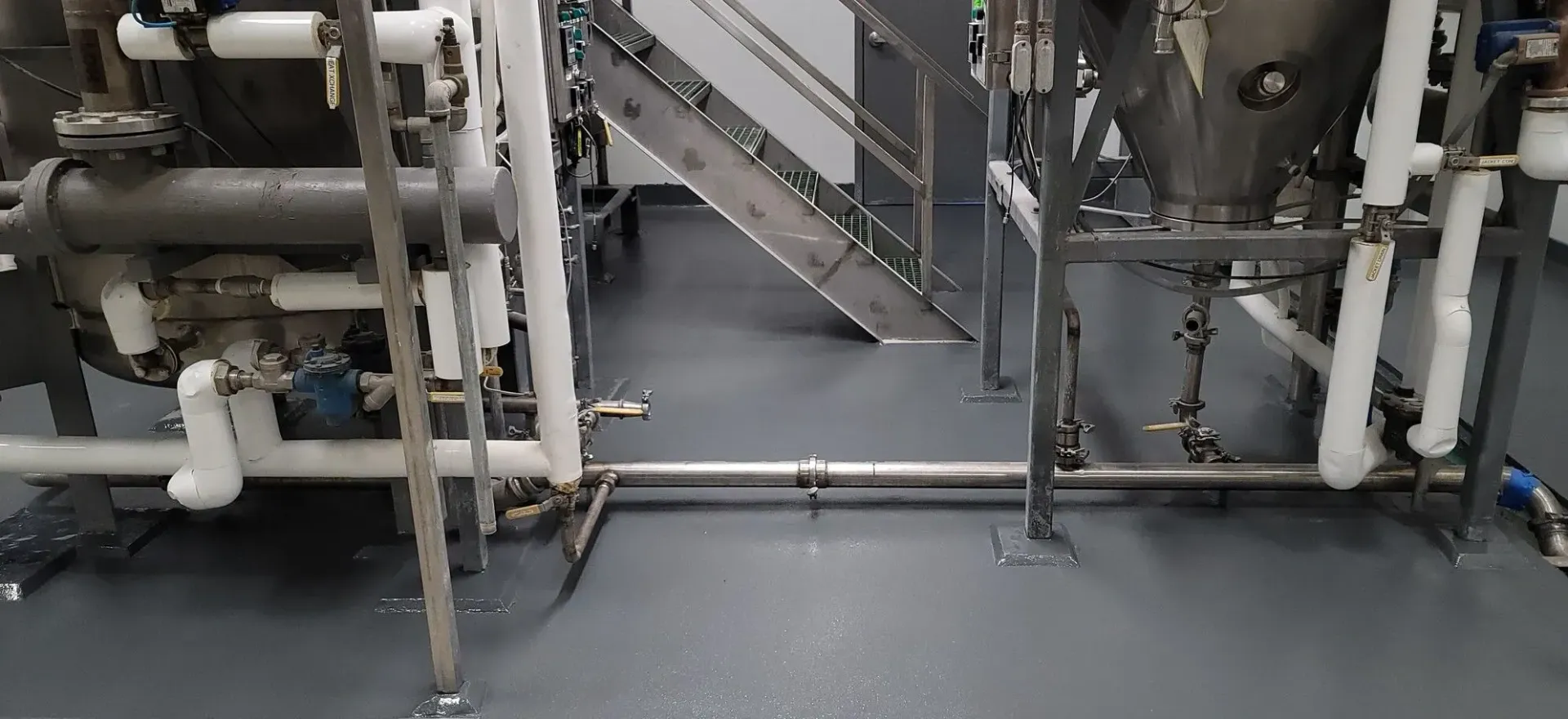

Epoxy coatings are a go-to solution for manufacturing plants thanks to their strength, chemical resistance, and seamless application. These coatings create a thick, protective layer over concrete floors, preventing cracks, stains, and wear even in harsh environments.

Pro Tip: For facilities dealing with electrostatic discharge (ESD), anti-static epoxy formulations are available to protect sensitive equipment.

2. Urethane Cement Flooring

Ideal For: Thermal shock areas, wet zones, food-grade environments

Urethane cement systems are incredibly resilient and outperform epoxy in areas exposed to extreme temperatures, moisture, or aggressive cleaning protocols. They’re also non-porous and resistant to bacterial growth, making them great for sanitary manufacturing spaces.

Did You Know? Urethane cement flooring can withstand thermal cycling from hot water washdowns, which would otherwise damage epoxy.

3. Polished Concrete

Ideal For: Medium-duty areas, warehouses, and facilities focused on aesthetics + durability

Polished concrete offers a sleek, high-performance surface that resists abrasion and requires minimal upkeep. While not as impact-resistant as epoxy or urethane, it’s a cost-effective solution for less aggressive areas of the facility.

Bonus: Polished concrete reflects light, which can improve facility brightness and reduce lighting costs.

4. Hybrid Systems (Epoxy + Urethane Topcoats)

Combining epoxy base layers with a urethane topcoat offers the best of both worlds—impact resistance, chemical protection, and UV stability. These systems are ideal for plants seeking a high-performance floor that can go the distance under any condition.

Flooring Zoning: Tailor Systems to Specific Areas

Manufacturing plants often have multiple environments under one roof. Use flooring zoning to match each area with the right material:

| Area | Recommended Flooring |

|---|---|

| Assembly lines | Epoxy or urethane cement |

| Forklift lanes | Epoxy with slip-resistant additives |

| Washdown areas | Urethane cement |

| Maintenance shops | Chemical-resistant epoxy |

| Warehouse storage | Polished concrete or epoxy |

Frequently Asked Questions

How long will industrial flooring last in a manufacturing facility?

With proper installation and maintenance, epoxy or urethane flooring systems can last 10–20 years, even in high-traffic environments.

Can you install flooring without shutting down production?

Yes. Many modern systems offer fast-cure technologies that allow for phased or overnight installations with minimal disruption to operations.

Why Professional Installation Matters

The performance of any flooring system starts with proper

surface preparation and professional-grade application. At

Extreme IFC, we tailor flooring solutions based on your facility’s traffic, environmental conditions, and safety needs. Our team uses advanced prep equipment and durable materials that ensure your floor performs from day one—and for years to come.

Ready to Upgrade Your Facility Floors?

Extreme IFC is an industrial flooring contractor that specializes in high-performance industrial flooring for manufacturing environments. Whether you're upgrading a production line or building a new facility, we’ll help you choose the right system for strength, safety, and long-term value.

Contact us today to schedule a free consultation and get expert guidance on building a floor that’s as tough as your operation.