The Benefits of Epoxy Flooring for Industrial Facilities

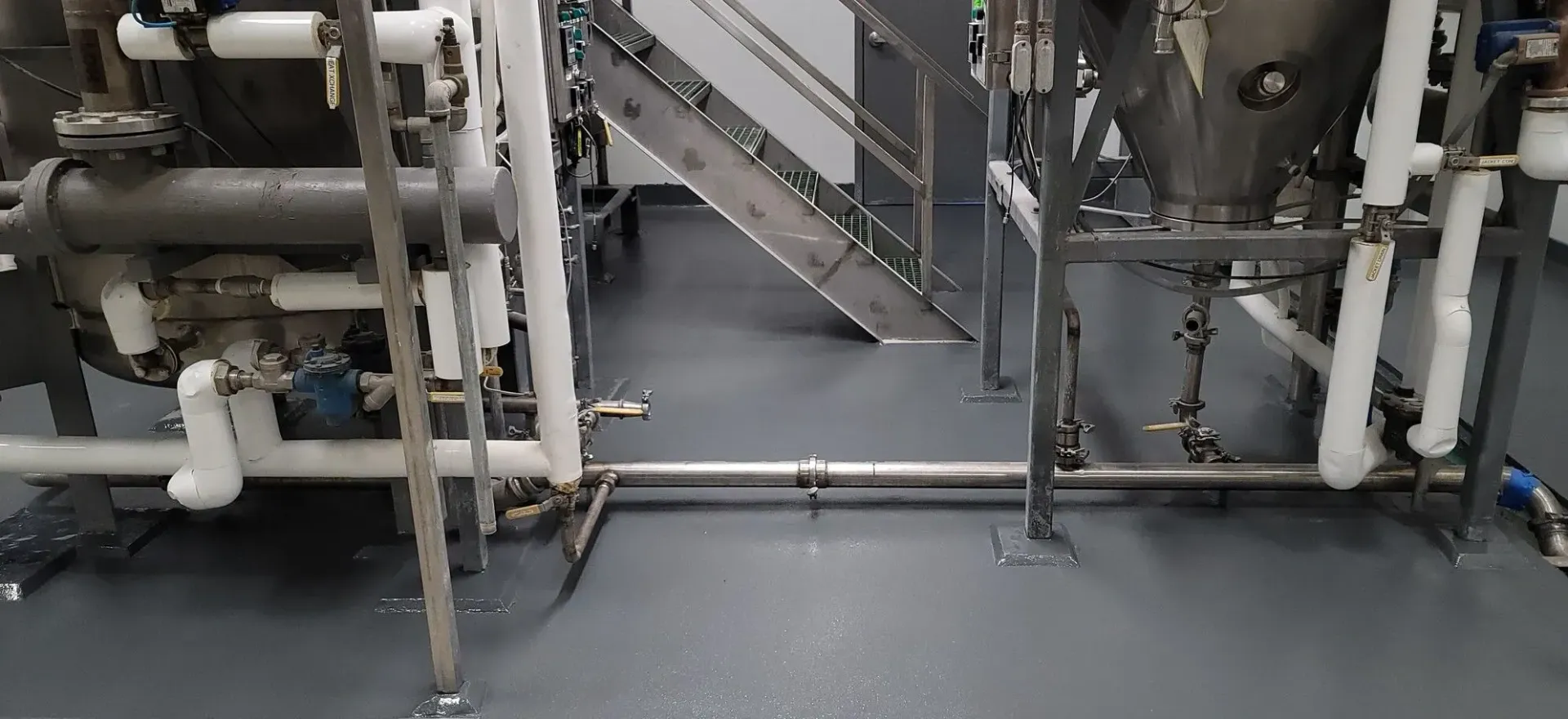

When it comes to industrial spaces, flooring needs to do much more than just look good. It must endure heavy machinery, constant foot traffic, and exposure to chemicals and other harsh substances. For facility managers searching for a high-performance flooring solution that blends strength, functionality, and long-term value, epoxy flooring checks all the boxes.

Epoxy coatings continue to be a popular choice for industrial environments, and for good reason. From warehouses to manufacturing plants, these floors are built to withstand tough conditions while offering additional benefits that can improve overall facility operations. Below, we’ll explore why epoxy flooring is ideal for industrial facilities and how it can address your specific challenges.

Durability Built to Last

One of the standout features of epoxy flooring is its unmatched durability. Industrial environments aren’t kind to floors. They endure the constant weight of forklifts, heavy machinery, and storage racks that can wear down traditional flooring quickly. Epoxy coatings form a tough, seamless surface designed to resist cracking, chipping, or peeling, even under heavy loads.

Warehouse managers, for instance, often struggle with concrete floors that develop cracks over time. These cracks not only disrupt smooth operations but also pose safety risks. Epoxy alleviates this problem by creating a sealed, damage-resistant layer that holds up against impact and abrasions, extending the floor’s lifespan.

Resistance to Chemicals and Stains

Many industrial settings, such as chemical processing plants or auto repair shops, deal with frequent spills of harsh chemicals, oils, or other damaging substances. Unlike porous floors that absorb stains or break down when exposed to potent agents, epoxy flooring resists chemical corrosion.

This resistance protects the surface from permanent damage and provides a clean, safe environment. For example, in a manufacturing setting where hazardous spills are common, epoxy flooring allows for easy cleanup, making sure that harmful substances don’t degrade the floor or create long-term hazards for staff.

A Safety-Forward Flooring Solution

Safety is a top priority in every industrial facility, and epoxy flooring can significantly contribute to a safer workspace. Options for slip-resistant coatings help reduce accidents, even in high-moisture areas. These slip-resistant finishes are especially useful in facilities like food and beverage processing plants, where liquid spills or condensation from equipment are everyday occurrences.

Additionally, epoxy flooring can improve visibility. Its smooth, glossy finish reflects light, enhancing brightness throughout the facility. A well-lit environment not only improves worker productivity but also helps prevent injuries, as hazards are easier to spot and avoid.

Easy Maintenance Saves Time and Money

Industrial operations thrive when efficiency is at the core. Epoxy flooring eliminates time-consuming maintenance, reducing the cost and effort required to keep the facility clean. The seamless surface resists dust, dirt, and debris accumulation, making it quick and easy to mop or sweep.

Unlike traditional concrete, which may require frequent patching or sealing to remain functional, epoxy eliminates the need for constant repair work. This reduction in maintenance not only saves on labor costs but also prevents operational downtime, making sure your facility runs as smoothly as possible.

Customization for Every Environment

Another major perk of epoxy flooring is its versatility. Industrial facilities vary widely in their needs, and epoxy coatings can be tailored to meet specific requirements. Color-coding can be used to designate safety zones, pathways, or storage areas, improving organization and workflow.

For environments requiring extra resistance, like manufacturing plants or aerospace facilities, epoxy can be improved with additional options like anti-static coatings for electrical equipment protection or thicker layers for warehouse durability.

Increased Professional Appearance

While functionality is a top priority, aesthetics still play an important role. Epoxy flooring offers an attractive finish that can give industrial spaces a more polished, professional look. Whether it’s applied to a showroom floor or a manufacturing plant, the clean, glossy surface creates an impressive and highly functional workspace.

Decorative options, such as flakes or metallic finishes, allow you to further boost the overall appearance of the facility. This can be especially beneficial for facilities that host client walkthroughs or require strict compliance with cleanliness standards.

Long-Term Cost Effectiveness

Epoxy flooring isn’t just an investment in your facility's present but also its future. By preventing costly repairs, withstanding years of wear and tear, and minimizing maintenance needs, this flooring solution offers one of the best returns on investment available for industrial spaces. While the upfront cost may seem higher than other options, its longer lifespan and reduced upkeep mean you’ll save money in the long run.

Ideal Applications for Industrial Epoxy Flooring

Epoxy flooring is perfect for a wide range of industries, including:

- Warehousing and Distribution Centers: Withstands forklifts, pallet jacks, and heavy inventory demands.

- Automotive Facilities: Resistant to oils, greases, and other fluids common in vehicle maintenance environments.

- Food Processing Plants: Non-porous surfaces prevent bacterial growth, while anti-slip options protect employees.

- Pharmaceutical Manufacturing: Meets hygienic requirements for sterile, contamination-free environments.

Wherever there’s a need for durability, chemical resistance, and low maintenance, epoxy flooring delivers unmatched performance.

The Right Flooring Partner Makes a Difference

At Extreme IFC, we take pride in delivering epoxy flooring solutions that meet the unique challenges of your industrial facility. Whether you need a heavy-duty coating for a warehouse or a slip-resistant system for a production floor, we’re here to provide a seamless solution tailored to your needs. Reach out today to discuss your next project and find out how we can improve your space with durable, high-performance epoxy flooring.

FAQs About Epoxy Flooring

How long does epoxy flooring last in an industrial setting?

Epoxy flooring can last 10-20 years in industrial facilities, depending on usage, maintenance, and the specific type of epoxy coating installed. Its longevity makes it an excellent choice for high-traffic environments.

Is epoxy flooring slippery?

Epoxy flooring can be made slip-resistant with the addition of specific coatings or aggregates. This is particularly valuable in areas prone to spills or high moisture, like industrial kitchens or processing plants.