The Evolution of Flooring: A Deep Dive into Cementitious Urethane Flooring Systems

Flooring is more than just a surface underfoot; it’s a crucial aspect of any space’s functionality, aesthetics, and longevity. Over the years, the flooring industry has seen remarkable advancements, and one such innovation that has revolutionized industrial and commercial flooring solutions is the cementitious urethane flooring system. In this blog post, we’ll take a comprehensive look at the evolution of flooring and delve into the intricacies of cementitious urethane flooring systems.

The Genesis of Flooring: From Primitive to Modern Solutions

Throughout history, humans have employed various materials for flooring, ranging from compacted earth and stone to wood and tiles. These early flooring solutions prioritized functionality and durability, catering to the specific needs of different civilizations and environments. However, as societies evolved and technological progress accelerated, so did the demand for more advanced flooring options.

The Rise of Modern Flooring Technologies

The 20th century witnessed significant developments in flooring technologies, with the introduction of materials such as vinyl, linoleum, and epoxy. These materials offered improved durability, ease of installation, and maintenance compared to their predecessors, marking a pivotal shift in the flooring industry. However, as industries and facilities demanded even higher performance standards, the search for more robust and resilient flooring solutions continued.

Enter Cementitious Urethane Flooring Systems

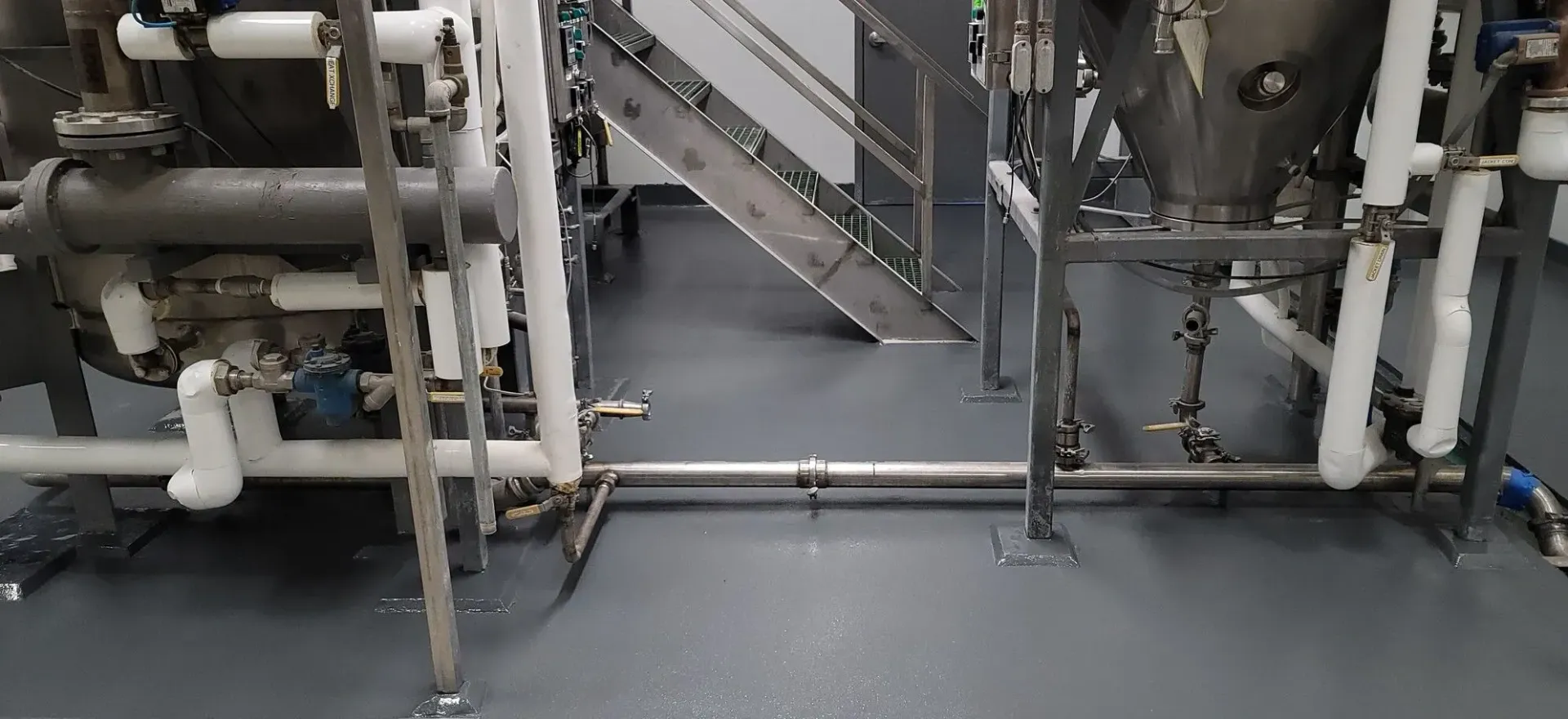

Cementitious urethane flooring systems emerged as a groundbreaking solution that combined the strength of cement with the flexibility and chemical resistance of urethane. This innovative fusion of materials resulted in a flooring system that surpassed traditional options in terms of durability, longevity, and versatility. Cementitious urethane flooring systems are typically installed in multiple layers, starting with a primer coat followed by a base coat and a topcoat, resulting in a seamless and monolithic surface.

The Advantages of Cementitious Urethane Flooring Systems

Exceptional Durability:

Cementitious urethane flooring systems are renowned for their unmatched durability, capable of withstanding heavy foot traffic, impact, abrasion, and chemical exposure. This makes them ideal for industrial facilities, warehouses, and food processing plants where floors undergo rigorous wear and tear.

Chemical Resistance:

One of the standout features of cementitious urethane flooring systems is their superior resistance to a wide range of chemicals, including acids, alkalis, oils, and solvents. This makes them suitable for environments where exposure to harsh chemicals is prevalent, such as laboratories and chemical manufacturing plants.

Hygienic Properties:

The seamless nature of cementitious urethane flooring prevents the accumulation of dirt, moisture, and bacteria, making it easy to clean and maintain. This makes it an excellent choice for environments that require strict hygiene standards, such as healthcare facilities and commercial kitchens.

Conclusion: Paving the Way Forward

As the demands of modern industries continue to evolve, so too will the need for innovative flooring solutions that can keep pace with changing requirements. Cementitious urethane flooring systems represent a significant milestone in the evolution of flooring, offering a blend of durability, chemical resistance, and hygiene that is unmatched by traditional options. As we look to the future, it’s clear that cementitious urethane flooring systems will continue to play a crucial role in shaping the built environment, providing reliable and long-lasting flooring solutions for a wide range of applications.