Epoxy or Polyurethane: The Better Coating Solution for Your Concrete Floor?

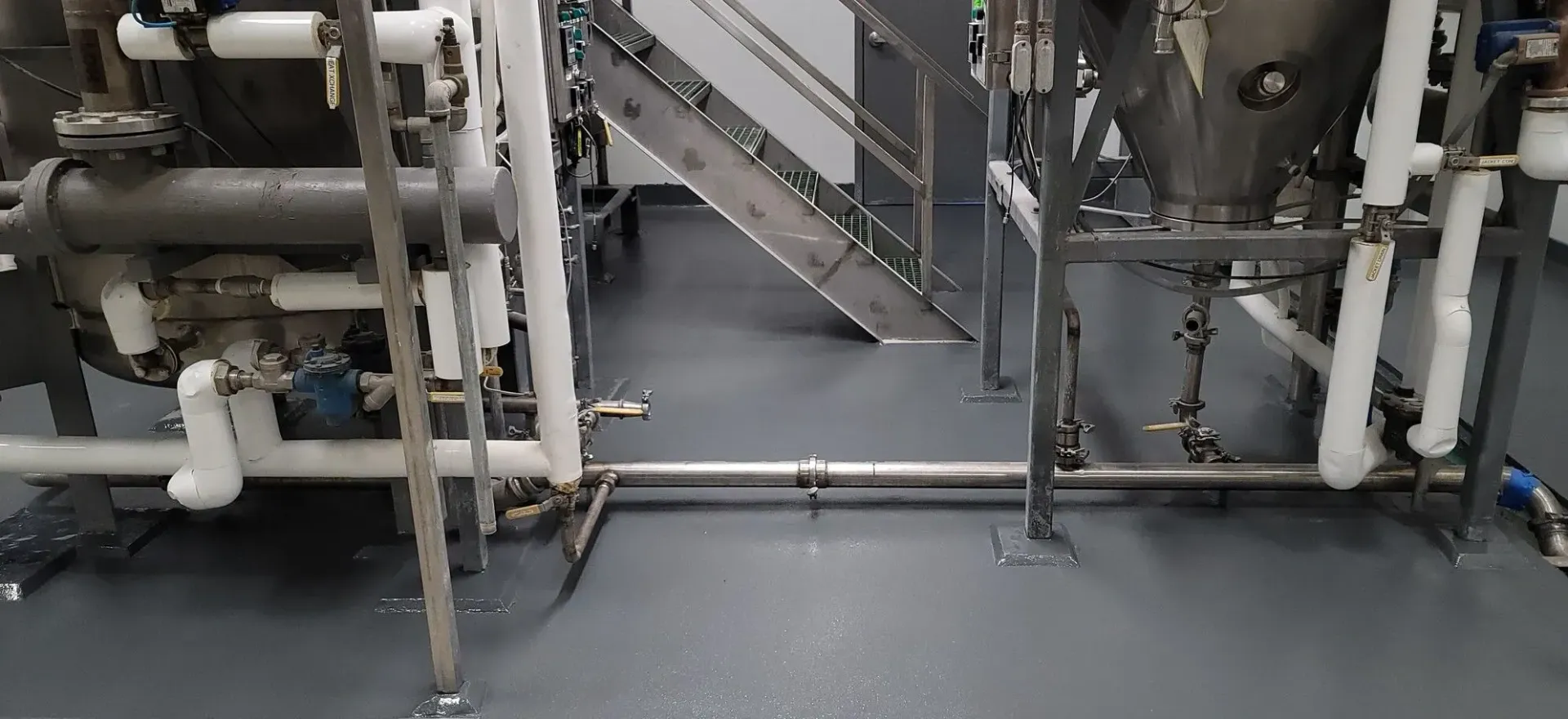

When it comes to choosing a coating solution for concrete floors, businesses and individuals often come across two options: Epoxy and Polyurethane (also called urethane). Though both thermosetting polymers are great choices for the application and offer a variety of advantages, such as chemical-resistance, durability, safety, better light reflectivity, and more, the choice of material may vary, depending on the requirement.

Why Choose Epoxy

A coating system is only as good as its initial bond with the concrete substrate. If you are looking for a concrete “resurfacing” solution for a hard, durable, impact-resistant surface, epoxy is generally a better choice. It mechanically bonds to concrete to provide a well-adhered system base that allows for subsequent build and topcoats. Depending on the requirement, you can choose from flexible, chemical-resistant, or fast-setting epoxies, and varying degrees of thickness, from 3 mils to 15 mils for a single coating. This thickness allows the coating to chemically bond to the epoxy primer, and self-level and fill minor concrete blemishes and hairline cracks. Epoxy also works well against hot tire pick up, scratching, and wear from abrasion The material is easy to install and relatively more cost-effective as compared to its floor coating counterpart.

Why Choose Polyurethane

One major difference between polyurethane and epoxy is it is much less thick, only about 2 or 3 miles and just about 60% or 70% solids. When heat is applied, the material turns into a durable solid, creating a high-performance floor surface. Though not an ideal coating option to apply directly to an existing concrete floor (because it doesn’t bond well with concrete), polyurethane is an excellent choice for UV-resistance and offers better chemical resistance for a broader range and concentrations of chemicals. Additionally, it offers excellent impact and abrasion-resistance as compared to uncoated epoxy floors, providing longer life. You can choose from a wide range of finishes, from satin to semi-gloss to high-gloss.

Final Thoughts

Both epoxy and polyurethane are good coating options and can be used in combination (applying a polyurethane topcoat over epoxy) for the ultimate protection of industrial or commercial concrete floors that are going to be heavily trafficked or constantly exposed to harsh, damage-causing chemicals.

Extreme IFC for Concrete Flooring Solutions in Georgia

Extreme IFC is your concrete flooring expert in Georgia. We have a wide range of options available for basic to highly customized and technical projects, and our experienced team can help you choose seamless flooring in Atlanta GA. Contact us for a design solution for your concrete surface that is durable, cost-effective, and can perfectly meet your flooring requirements.