Decoding the Cost Factors of Industrial Flooring Services in Georgia

Industrial flooring is a crucial component of any manufacturing or industrial facility in Georgia. It not only provides a durable and safe surface for operations but also contributes to the overall efficiency and productivity of the workspace. However, when it comes to investing in industrial flooring services, understanding the various cost factors involved is essential for making informed decisions. In this blog, we’ll delve into the key elements that influence the cost of industrial flooring services in Georgia.

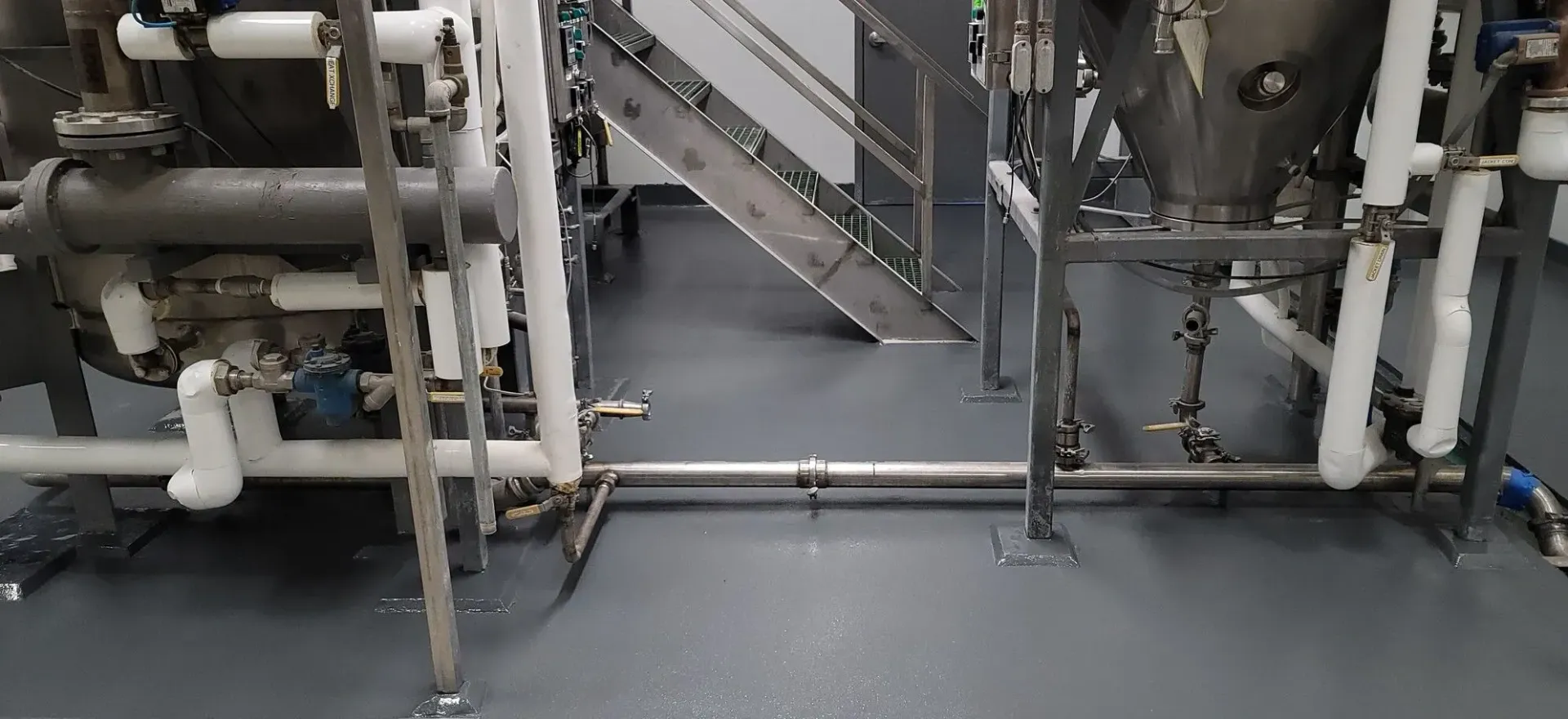

Type of Flooring Material

The choice of flooring material significantly impacts the overall cost of the project. Different options, such as epoxy, concrete, vinyl, or rubber, come with varying price points. Epoxy flooring, known for its durability and chemical resistance, may have a higher upfront cost but can offer long-term savings in maintenance and repairs.

Surface Preparation Requirements

Proper surface preparation is critical for ensuring the longevity and performance of industrial flooring. Factors such as existing floor condition, substrate repairs, cleaning, and leveling can influence the cost. Extensive preparation work, such as shot blasting or diamond grinding, may incur additional expenses but is essential for achieving optimal adhesion and durability.

Size and Layout of the Facility

The size and layout of the industrial facility directly affect the total cost of flooring installation. Larger spaces require more materials and labor, resulting in higher overall expenses. Complex layouts, corners, and obstacles may also increase the complexity of the installation process, impacting the final cost.

Customization and Design Requirements

Customization options, such as decorative patterns, logos, or color coatings, can enhance the aesthetics and branding of the industrial space but may come at an extra cost. Intricate designs or specialized coatings may require additional materials and labor, contributing to the overall project cost.

Installation Method and Labor Costs

The chosen installation method and the expertise of the labor force play a significant role in determining the cost of industrial flooring services. Professional installation by experienced contractors ensures quality workmanship but may come with higher labor costs. Factors such as accessibility, project timeline, and safety considerations can also impact labor expenses.

Additional Features and Add-Ons

Optional features or add-ons, such as anti-slip coatings, moisture barriers, or chemical-resistant properties, can enhance the functionality and durability of industrial flooring but may entail extra costs. Assessing the specific needs and requirements of the facility is crucial for determining the necessity and feasibility of such additions.

Warranty and Long-Term Maintenance

Consideration of warranty coverage and long-term maintenance requirements is essential for evaluating the overall value of industrial flooring services. Some providers may offer warranties against defects or premature wear, providing added peace of mind. Additionally, factoring in maintenance costs and schedules can help estimate the total cost of ownership over the flooring’s lifespan.

In conclusion, understanding the cost factors of industrial flooring services in Georgia is essential for making informed decisions and budgeting effectively. By considering factors such as flooring material, surface preparation, facility size, customization options, installation method, and long-term maintenance, businesses can assess the overall investment required for achieving durable, functional, and visually appealing industrial flooring solutions.